What is LED Linear Light? their Application, Fixtures and Maintenance

Linear lights are one of the most popular and widely used lights in modern architecture and lighting. The high variety of linear lights in their construction, installation, luminous flux, and light quality has made them important as recessed, surface mounted, and pendant linear lights for walls, and ceiling lighting in residential, office, and commercial spaces.

LED linear lights have multiple usages varying from exterior and facade, narrow under-cabinet light lines, from widths up to 70 meters to 30 cm, and from continuous lines to a variety of shapes such as square, rectangular and L-shaped or angles. As mentioned, these are for offices, galleries, stores, modern houses, etc., all of the variations of the LED linear light sales market are based on the concept of space architecture, which has a significant impact on the price of the linear light and its accessories, and is fully introduced in this article.

New LED linear lights with new technology, including modular linear lights that have the ability to control all the components of the light, light efficiency and providing sufficient light, quality of color appearance, and how to customize it based on the elements used in architecture and the interior design of the space have become much more advanced, and in this way, you can have quality linear light in various shapes, including continuous lines, squares, rectangles, or any other geometric shape. This feature is the winning card of lighting for architects and interior designers because linear lights, in addition to providing proper lighting, are also used decoratively and double the visual beauty of the space.

In the following, all the details and complete introduction of linear lights, their installation, quality of light, color, design, and construction method, and lighting with them have been discussed for you to choose the best linear light for your desired space and customize it based on your project needs.

The History of Linear Lights

Throughout history, the construction industry and other related businesses have made great progress and have developed at a high speed. The developments related to lighting and lighting industries were progressing at a very low speed until 50 years ago. Of course, this development gained significant speed after the widespread use of LED technology in the early 2000s, which also includes linear lights.

Until the early 1950s, there was practically no such thing as a linear lamp. In this period, linear lights were used as a replacement for linear shutter panels that were used in most office spaces at that time. The old fluorescent lamps are also among the ancestors of today’s linear lamps. After the advancement of technology and the widespread use of computers, a new problem arose for consumers of lighting devices, and this problem was nothing but the glare on the monitor screen. Employees and consumers who used computers for their work, while working under the light of old linear lights, had the problem of glare and work disruption.

In the following years with the development of linear lamps, an attempt was made to solve this problem, for example, the first generation of T5 linear lamps was unveiled. In these lights, the problem of glare was solved to some extent, but all these lights still used the same 1950s technology and fluorescent lighting.

Between 2010 and 2011, the advancement of LED technology created a revolution in the field of lighting, and various types of linear lights such as LED strips emerged quickly. Finally, by identifying and solving the problems related to LED filaments, modular linear lights with much more light, low glare, and in different types of one-way and two-way, with a small and large width, RGBW, Dali, and other types of phenomena were introduced.

Do you want our catalogs and price list?

What is a modular linear light?

In modular linear lights, each part of the light source can be replaced separately, so there is no need to replace the entire light source for lamp maintenance and repair.

Why is a modular linear light better than an integrated linear light or LED string?

Due to the fact that in modular linear lights, by burning a chip, the desired part can be easily replaced without the need to replace the entire light source, the maintenance cost of these lights is much lower than integrated linear lights. In addition, the process of installing and maintaining these lights is also easy, and there is no need to install or replace a single light line. As a result, the lifetime of the linear lamp is increased and it provides better light.

Types of linear lights based on the performance system

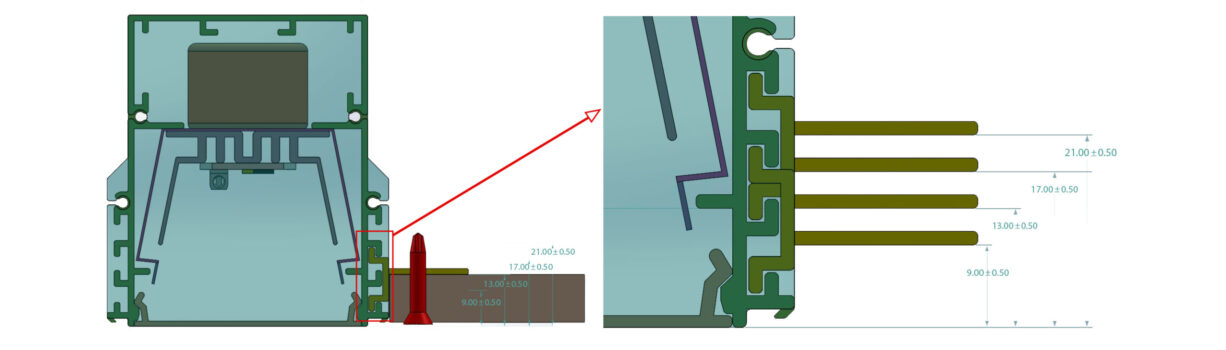

The difference between the Zhaga standards light engines and other linear light modules

The best linear lights in terms of quality are Zhaga standard linear lights which is a global physical standard that monitors the dimensions of linear light engines. Modules with Zhaga standard are produced in dimensions with 7 cm coefficients and work by constant current driver.

In the general category of LED drivers, the lights operate either with a constant voltage or constant current driver. If a constant voltage driver is used in the linear light, it is necessary to use electrical resistance to keep it constant. As a result, with the use of resistance, part of the current is converted into heat which enters the components of the lamp that reduces its lifespan. In addition, due to the presence of these resistors, the light at the beginning and end of the linear lamp may differ and the lamp may lose light along the optical line. All kinds of LED strings and strips are in this category.

In linear lights with a constant current driver and module, there is no need to use resistance anymore. Therefore, there will be no extra heat or light loss in them. In addition, by using Zhaga’s standard constant current modules, as this is an international standard and is known all over the world, you can easily get the required light engine from anywhere.

Types of linear lights based on application

In general, any lamp in which the light source shines in a line and not round or square is called a linear lamp or line lamp. According to this definition, even old fluorescent lamps are considered linear lights. But here we only mention LED linear lights with more advanced technology, including modular linear lights. The way to install a linear light is in the form of a built-in (recessed linear light) , surface mounted and pendant, each of which will be described separately. The use of linear lights in different spaces, including offices, commercial complexes such as stores, or even residential spaces, differs depending on the type of their installation.

Recessed linear light

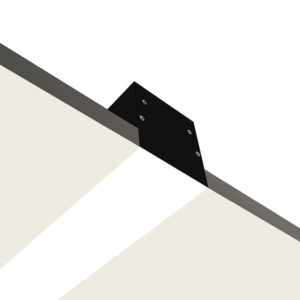

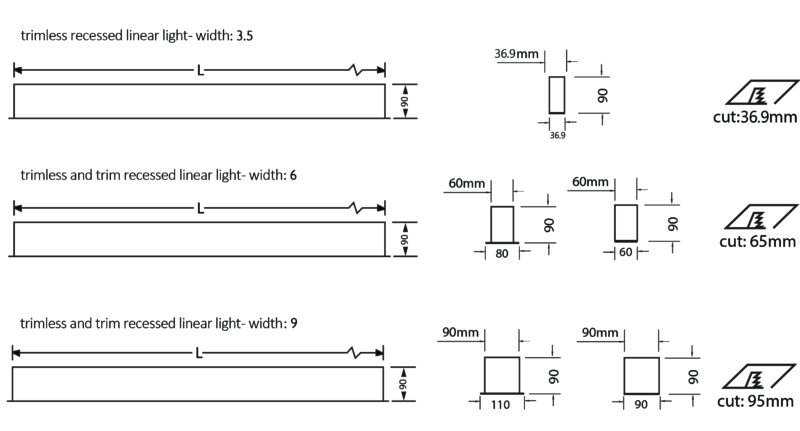

Recessed linear lights are considered to be among the most minimal and beautiful lighting devices. In these lights, the entire body of the lamp is placed inside the wall or ceiling, and only the diffuser or cover is visible on the light source to provide sufficient illumination. Recessed linear lights are divided into two groups, trim and trimless, and can be made in all kinds of lines and geometric shapes.

Recessed linear light (trim)

In recessed trim linear lights, around the light diffuser, there are edges about 1 cm wide on each side. These edges make it easy to install the light and if there are errors of 1 cm when making a cut or groove on the ceiling to install the light, even with the edge, it will be covered. Built-in linear lights are adjusted from the inside by a means of a butterfly-shaped fastener placed behind the light body, and by rotating the fastener around the lamp, the body is fixed in the ceiling.

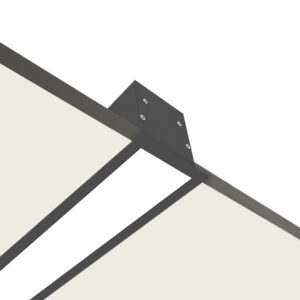

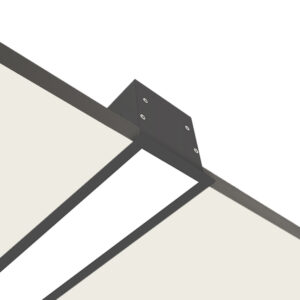

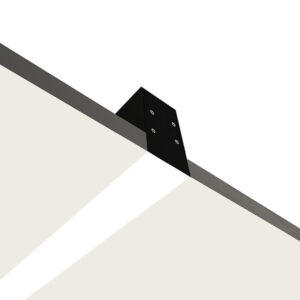

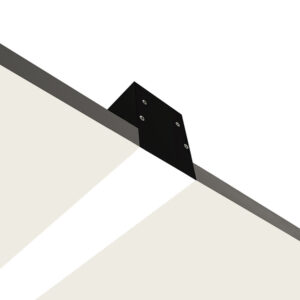

Recessed trimless linear light

As mentioned earlier, the use of recessed linear lights increases the beauty of the space. Now imagine that your linear light inside the ceiling does not have any edges. In other words, there is no trace of the lamp body, and only the light source can be seen integrated with the roof’s structure. This is one of the advantages and beauties of the built-in linear light without edge or trim-less. In the trim-less linear light, all the additions around the lamp are removed and an extremely beautiful and minimal appearance is created in the lighting of the space. The light of a linear lamp without an edge is still the same as other linear lights, and the only difference is the appearance of the lamp and the way they are installed.

A recessed linear light without an edge is usually used as a decorative light (a recessed trimless linear light with a width of 4 cm) or a general light (a built-in trimless linear lamp with a width of 6 cm & 9 cm).

The installation of this light is done before the completion of the Knauf or other ceiling structures. In fact, in the trim-less linear light, the edges of the lamp are not removed, but moved to a higher altitude than the light source, so that it is placed behind the lampshade and cannot be seen. After placing the lamp along with its edges behind the plaster, the small gap between the lamp and the ceiling is puttied and then by painting the surface of the ceiling, this gap is completely removed and the lamp is completely integrated and seen with the roof’s structure.

How to install a trimless recessed linear light

The edgeless linear light is different from other linear lights in terms of installation. As a result, they look more beautiful than other linear lights. The trim less linear light, however, in terms of the appearance of the body profile, is not much different from other built-in linear lights.

The installation of linear light without edge is done before the completion of the Knauf structure. In order to do this, first, the lamp profile is connected to the Knauf metal grid from above. Then, after placing the Knauf panels, the edges are connected to the surface, and finally, with putty and paint, all the grooves and specific points are gone and only the light source is visible.

Suspended linear light

Suspended (pendant or hanging) linear lights, which are among the most popular and beautiful lights in the market, are produced like other surface linear lights regarding their structural design. These lights are hung from the ceiling by means of two types of hangers, i.e. cable hangers or telescopic hangers, in order to provide both sufficient lighting and visual beauty in spaces where the ceiling height is high or where a decorative light is needed. To use the hanging cable, the lamp is established by means of a current wire placed parallel to the hanging cable. But in the second case, using a rigid pendant that is thicker than the cable, the current wire passes through the cable and there is no need for a separate wire.

LED pendant lights are divided into two categories:

A. One-side suspended linear light;

in these lights, the light source is placed at the bottom of the lamp and the light shines from the side of the lamp towards the ground.

B. Double-side suspended linear light;

in double-sided pendant linear lights, two rows of light engines are placed at the top and bottom of the light. Thus, these lights have the ability to illuminate the ceiling (up light) and the ground (down light) separately. This possibility makes it possible to turn on each of the lights that shine upwards or downwards separately. By illuminating the space above the lamp, these lights are usually installed on ceilings that have the light color or the ceiling element gets a beautiful effect with the light.

Surface mounted linear light

In terms of the way of installation and placement, the linear LED surface lights are easily installed inside the grooves between the wooden and metal baffles or on the ceiling and wall with screws and dowels. Surface-mounted linear lights are used in spaces where a groove cannot be created inside the wall to provide sufficient light and placement of the light, or the height limit prevents the installation of pendant linear lights. In these lights, the entire body of the light is considered and seen as a part of the decoration. Therefore, many linear lights are produced with customized body colors so that they can be matched with the decoration of the desired space. Modular surfaced linear lights can also be customized by providing the right luminous flux in all geometric shapes.

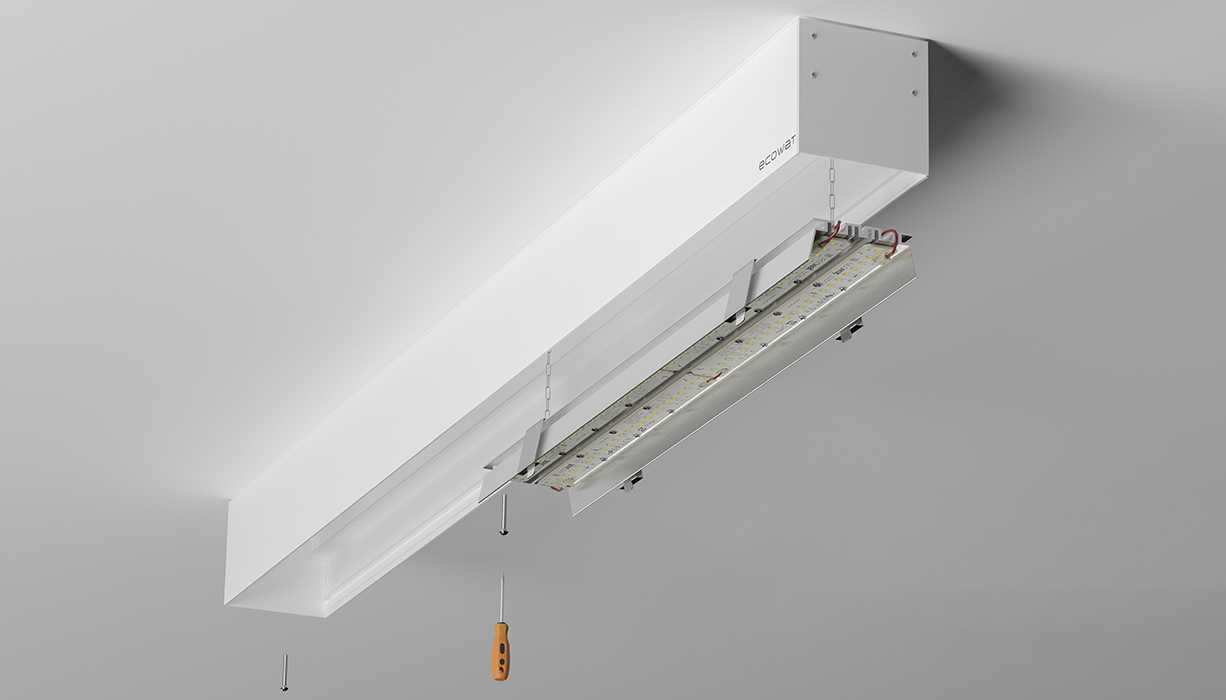

Showing the cross-section of the Ecowat modular linear light

LED linear light components

In general, a linear LED modular light includes the following components:

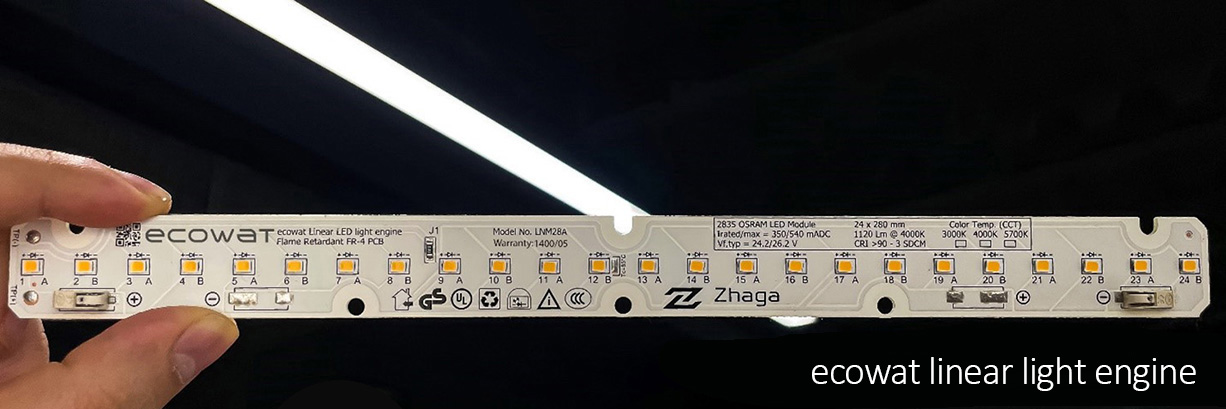

LED engine with Osram chipsets:

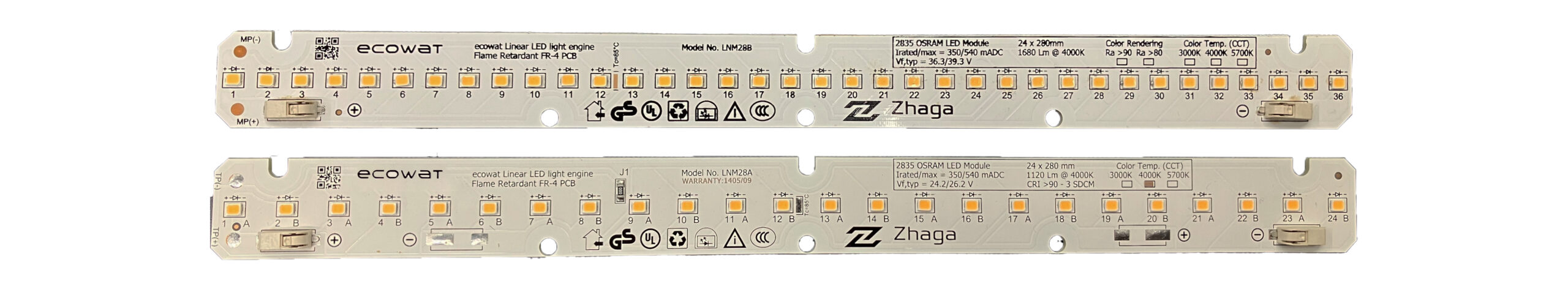

PCB boards on which LED chips are placed as lighting sources. These lighting engines, which have the Zhaga standard and Ecowat production, are connected to each other by means of push sockets or the ones with the ability to connect without the need for tools. The number of chips on the 7 cm module is 6, on the 14 cm module is 12 and on the 28 cm module is 32 or 48 depending on your choice.

In Ecowat LED engines, We use high-qualify Osram chipsets with CRI>95 (Color rendering index) and SDCM<3 (Standard Deviation Colour Matching).

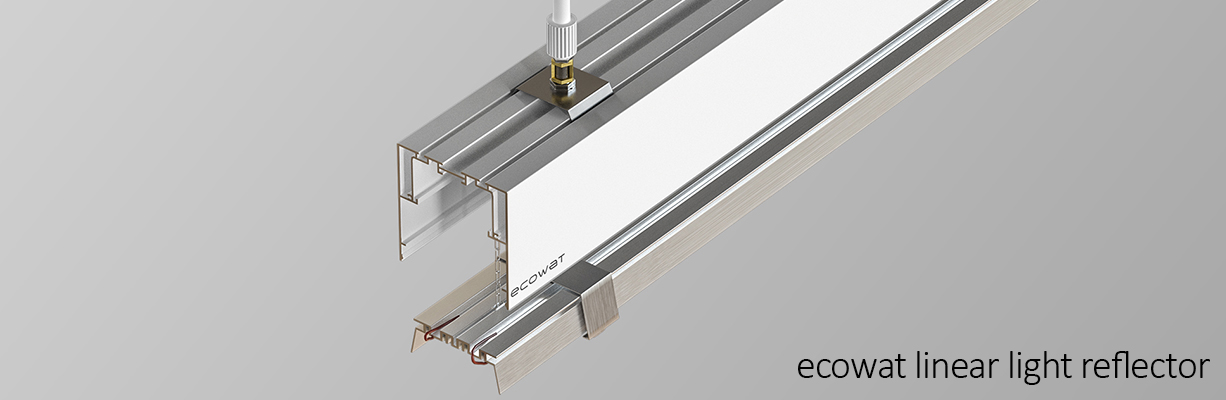

Hitsink:

cooling the inside of the lamp and reflecting the light is dependant on the reflector or the heat sink of the linear light. This aluminum piece is placed inside the light in a way that the light engines and the driver are screwed to its two sides. It is better to use a linear light whose reflector is connected to the body by a chain since when you need to repair and replace lamp parts, you can easily detach and hang it from the light body by means of reflector clamps and perform the replacement operation easily.

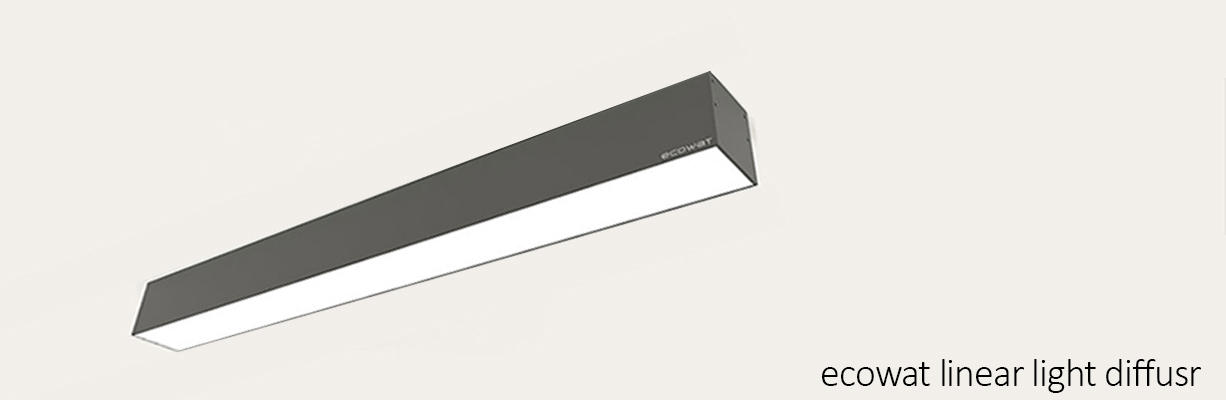

Diffuser:

The diffuser is a milky-colored cover, usually made of polycarbonate, which is placed on the body of the linear light and in front of the light source to prevent the glare of the light source and to spread the light evenly. When choosing a linear light, use a lamp whose diffuser is anti-UV to prevent harmful rays from the body and skin.

LED driver:

The beating heart of an LED light is its driver. In linear lights, the driver is usually placed inside the body and behind the reflector. Of course, this piece may be outside the body of the lamp and is very thin, but in this case, it should be ensured that there is no danger and that it is isolated.

The best linear light drivers are those that do not flicker. The existence of flicker or flickering of light may cause headaches and fatigue in human eyes and thus make the people in the respective space feel uncomfortable. Flicker-free lights do not tire the eyes in any way. Also, high power factor (PF>95%) and low harmonic distortion (THD<10%) are considered reference standards in construction standards, especially in large commercial units, and your lights’ driver should ensure that there is no disturbance in the electricity network.

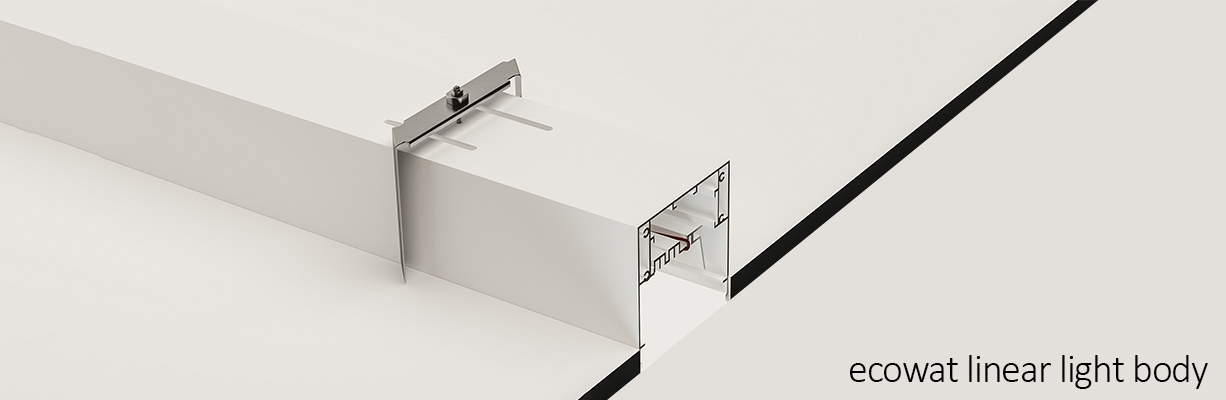

Aluminum body:

The best linear lights are the ones that are placed inside an all-aluminum body, because the aluminum material causes sufficient cooling of the light, maintains and controls its temperature, and thus increases the life of the light.

Another important point regarding linear light bodies, where the reflector, light engine, driver, and connection wires are placed inside, is the issue of their sufficient resistance against the pressures of the structure. The body of the linear lamp must be designed in a way that it neutralizes the pressure around the ceiling structure inside the ceiling and prevents the compression of the body and as a result, the protrusion of the diffuser so that the linear light can be seen uniformly from below.

For example, in the design of the body of Ecowat linear lights, two aluminum cans are used around it, so that the extra pressure applied to the light’s body is neutralized and its strength is maintained. This point was implemented due to the sensitivity of the architects in the absence of protrusions in the linear light.

The size and dimensions of the linear light

One of the limitations of modular linear light production is that you may not be able to have a linear light that exactly matches the dimensions you want as the light engines are made in specific dimensions and placed together, and the final dimensions of the light always have a tolerance. On the other hand, the use of LED filaments, despite the ability to cut in desired dimensions, has many disadvantages, which were explained previously. These things can be worrying for designers and architects who are very careful in executing their plans. Ecowat’s solution for this problem is the production of Zhaga standard linear light modules in different dimensions.

Our linear light modules are produced in dimensions of 7, 14, and 28 cm so that during the construction stage, the light modules can be arranged next to each other with a more open hand. In the worst-case scenario, in this way, the Ecowat linear lamp should have a maximum difference of 3.5 cm from your desired dimensions. With our standard light engines, you can always have a linear light according to the length you want using the linear light.

Do you need a brighter linear light?

The use of a brighter linear light that, in addition to the decorative aspect, illuminates a large space is one of the wishes of many consumers and building owners because the decorative aspect of the linear light is generally considered more than its light value. There is an answer in our product portfolio to solve this problem. Ecowat high-density light engines are the solution to this problem. In the general Ecowat linear light series, each meter of Ecowat linear lamp consumes about 32 watts per meter, if using the Ecowat high-density light engine, is possible to use a light with a power of 45 watts and a luminous flux of 4300 lumens per watt, in compliance with all standards.

In the picture below, you can see two 28 cm modules produced by Ecowat. There are 48 chips in the first module and 32 chips in the second module. The first module, which is a high-density Ecowat light engine, is brighter than the second one.

Where can the linear light be installed?

One of the advantages of linear lights is that due to the variety of installation methods, they can be used in all kinds of spaces, from inside the plasterboard to on the wall and under the cabinet and the like. As mentioned, linear lights are classified into the following types based on their installation;

- Recessed linear lights: are used for installation inside Knauf, plaster, Gypsum , MDF, and similar items.

- Surface-mounted linear light: for installation on the ceiling, between wooden baffles or metal grooves, or for installation on the wall, lighting can be done in the best way using a surface-mounted linear lamp.

- suspended linear lights: Are used to hang lights in normal or exposed ceilings, or in high-height spaces. These lights can be used both as one-way suspended linear lights (downlight) and double-side suspended linear lights (uplight and downlight).

Which spaces are linear lights used for?

Ceiling linear lamp or wall linear light, in-ground linear light, or cove light linear light. All of them are the most popular ways of using linear lights in various spaces, from artistic and decorative spaces such as galleries, studios, and cafes to office spaces. Therefore, we divide the applications of linear lights in the interior into several commercial, office, and residential sectors.

Brilliant ideas for retails lighting with linear lights (stores and commercial space)

Linear lighting of stores, showrooms, or large commercial centers is very effective in attracting customers and creating visual appeal for the goods and services provided. Retail lighting with linear lights includes general and decorative lighting or a combination of the two.

In addition, the use of a light with a color rendering index higher than 95 (CRI>95) makes the true color of the goods and objects placed in the store visible, and thus the problem of changing the color of the purchased goods does not arise for customers. In the following, some interesting ideas for using linear light in the interior design of stores, showrooms, and commercial spaces have been discussed;

- Using linear lights, you can guide customers and visitors to the store and commercial space from one part to another and finally to the desired part, because the human eye unconsciously follows the lines and thus the arrangement can highlight the part of the store that is more important.

- The use of pendant linear lights in high-height spaces can help to illuminate and better the visibility of the products placed in the store and showroom. For this purpose, you can use a hanging linear lamp with a width of 6 cm so that the light is spread sufficiently and it has the beauty and elegance of a decorative light. If you have chosen a special color for your desired space, you can order your linear light in your desired color you want to add a special combination of color and light to your decoration.

- You can use linear lights with geometric shapes such as squares, triangles, circles, or custom shapes for the showroom and store center. This method makes the center of the showroom be seen more as the flower of the store and the geometric shapes convey a sense of modernity and up-to-datedness of store.

- If the plastering or plastering of the space has not yet been completed and there is a possibility of creating a groove inside the ceiling or wall, using a built-in linear lamp can create a minimal and at the same time elegant and beautiful effect inside the space. In spaces with a high height, you can create more light by purchasing a 9cm width double line recessed linear light and fully provide the lighting of the space. If it is not possible to create a groove inside the wall, both surface linear lights and pendant linear lights are among the most popular lights for lighting modern commercial spaces.

- If you have used wooden baffles in the decoration intended for your space, use a linear light in the empty space between the baffles. Irregular placement of these lights in different parts of the ceiling and baffle doubles the beauty of your space.

Brilliant ideas for office lighting with line lights

In office lighting, there are two very important points that must be taken care of, in the design and selection of lights. The first point is to create enough lighting for the employees and the second point is to use a light without flickering to prevent eye fatigue and headache for the employees. For this purpose, to use a linear light, you must use lights without flicker or blinkers, and to create lighting, it is also necessary to pay attention to the height of the light installation. In addition, linear lights do not hurt the eyes due to the indirect and diffused light. For this reason, the employees and those present in the office space will not feel uncomfortable. If you want to light an office space, pay attention to the following points;

- If the desired office space has a high height or an exposed ceiling, without a doubt, the best lighting option is hanging linear lights. Due to the fact that linear lights, especially modular linear lights, can be made in customized dimensions, you can place a hanging linear light according to the length of the desks, so that every workspace is adequately lit and the dark spots on the desk will disappear. Considering that the top of the desk is not a place for people to pass, you can reduce the distance between the light and the floor more than other spaces, so that by reducing this distance, more light can be obtained.

- To light the meeting table or large tables, use rectangular or square linear lights in the dimensions of the table. With this, the entire table space will be sufficiently lit and will also have a unique effect on welcoming clients or employees.

- If an integrated and uniform ceiling such as Knauf ceilings is used for the design of the desired space, you can go for a two-sided hanging linear light that has both uplight and downlight, and each side of the lamp can be turned off and on separately. Illuminating the upper space means the ceiling and the lower means the ground.

- One of the most important parts of lighting is the entrance part of the office unit or the entrance counter because it shows the first view of a well-equipped office and is also very effective in attracting clients. Therefore, to illuminate it, use different linear lights in the entrance part of the space. A built-in linear lamp without an edge or a surfaced linear lamp with a customized body color matching the organizational color of the collection is among the best lighting devices for this space. In addition, at the top and bottom of the entrance table or around the logo of the brand or collection, use cove light using a T5 linear light to give it a decorative effect and also to distinguish the table from other parts of the space.

Brilliant ideas for home lighting with linear lights

Houses and residential spaces are one of the most attractive spaces for lighting using lights and linear lamps. Linear lights can be used in different ways in different parts of the house, including the kitchen, living room, and bedroom. For the modern lighting of the residential space with linear lights, each part of the house is described separately.

Kitchen and dining room lighting with linear lights;

Certainly, the kitchen is one of the most important and influential parts of the house in conveying the sense of the beauty of the space. Due to the necessity of creating comfort for working in the kitchen and visual beauty, its decoration and proper lighting are among the sensitivities of decoration, especially for women. By using a hanging or surface-mounted linear ligjt in the kitchen, including above the counter, both the space is well-lit and it gives a modern and up-to-date look to the kitchen. One of the advantages of linear lights is that you can customize them in the direction and shape of the kitchen plan. For example, in an L-shaped kitchen, you can order your linear lamp exactly in an L shape.

About 800 lux of lighting is needed for the lighting of the dining area so that you can enjoy your food easily and provide enough lighting to display the visual beauty of the food. Therefore, taking into account that the top of the dining table is not a place for people to travel, it is possible to create more lighting on the table by using a hanging line lamp and bringing it closer to the table. Make sure that you do not use double-line lights for this space so that its high light does not cause glare and eye irritation while eating.

The lighting of the living room and reception area with linear lights;

The living room is the heart of the house. Most gatherings and the most presence of guests take place in the largest part of the house, i.e. the living and reception area. To illuminate this space, at least 600 to 700 lux of light is needed to emit beautiful lighting the space. Considering that the objects placed in the reception area, such as sofas, tables, chairs, televisions, etc., have relatively large dimensions and take up a large part of the space, therefore minimal space lighting can prevent crowding and make the space look bigger.

Therefore, the built-in linear light, especially the trimless linear light, is one of the best options for lighting the living room, which can be used both as a linear ceiling light and a linear wall light.

If the ceiling of the reception hall is very high, use a linear light with a width of 9 and two lines to spread more light Also, for lighting the grooves inside the knauf or using hidden light in the reception, using T5 linear lights is the best alternative to strip lighting, because the light quality is much better and has a longer lifespan.

Bedroom lighting with linear lights;

Two types of lighting are usually needed for bedroom lighting. The first is general lighting, by means of which daily activities, study, work, etc. can be done in a private room. The second type is indirect light, which is used as a low and relaxing light for resting. By using the two-way hanging linear lamp, you can provide both types of light using a light in a beautiful position. In this way, by lighting the lower part of the light, general light is provided, and when the lamp is turned on, it shines on the ceiling and indirectly, causing the lighting of the sleeping lamp.

If you want the space around the bed to be lit as well, use a built-in linear light that extends from the ceiling to the wall around the bed and illuminates it.

Which linear lamp should we use for lighting?

There are many varieties of linear lights in the market. The price of existing linear lights is determined based on luminous flux, quality of color appearance, performance system, lamp body, and warranty, covers a very large range and can be changed based on the architectural idea. For lighting with linear lights, naturally, you should first consider the usage of the desired space. If you need linear lights to illuminate your interior, the best and highest quality lights available in the market are Zhaga standard modular linear lights.

Different kinds of executive projects with Ecowat modular linear lights

The amount and quality of an ideal light, and the ability to customize types of installation, have made linear lights to be used in all spaces, from shops and offices to residential spaces. In this way, Ecowat linear lights have been used in all commercial, office, and residential spaces, and since their existence, they have been implemented many times in all kinds of projects with the strong reception of interior designers, architects, lighting designers, and employers.

Click button below to view our linear light projects:

What is the brightness of the linear light?

In general, the huge variety of linear lights in the lighting market has caused each of them to have a different level of brightness compared to other linear lights, but in order to be able to compare and better estimate the brightness of each light in the space, using Ecowat modular linear lights and With the help of Dialux plugin, the lighting of the space is simulated.

In this simulation, a room with a length of 4 meters and a width of 3 meters, and a height of 3 meters is considered in order to create an illumination of about 500 lux with the intention of providing average general lighting. The important point is that all the samples used in this simulation are surface-mounted linear lights, and by using hanging linear lights, you can create more illumination on the surface by bringing the light source closer to the ground.

In the first picture, a linear light with a width of 6 rows and a size of 3.5 meters is used to light up the space with 500 lux.

How linear lamps are maintained?

One of the sectors where the many advantages of modular linear lights are evident in this sector. For the maintenance and repairing old and traditional linear lamps or LED strings, the entire light source and sometimes the lamp had to be completely replaced, but in modular linear lights, it is possible to replace only the damaged or burnt part in case of a problem. Consequently, the cost of repairs and maintenance is reduced dramatically.

In modular linear lights, if any module burns out, the same module is easily separated from others without any tools. It also separates from the reflector body with a screwdriver. Then it can be replaced with another standard Zhaga module. This also applies to other parts and tools of the linear light and every part, even the driver of the light, can be easily separated and replaced as all the wire connections are established by push sockets or push buttons and their separation can be done easily.

In the second image, similar to the first one, a linear light with a length of 3.5 meters has been used, this time using a linear light with a width of 9 meters. Due to the fact that the type and number of a light source as well as the power source are the same in Cut 6 and Cut 9 single line lights, both lights have created the same level of brightness. The difference between these is the amount of light spread. In the linear lights of section 9, due to the larger cross-sectional area from which the light is emitted, more light is spread into the space, but the intensity of the light appears to be less due to the fact that it shines on a larger surface.

In the third picture, a 2-meter-long cut-9 linear lamp is used to brighten the room with 500 lux. As we know now, two rows of modules are used side by side in two-line cut 9 linear lights, and then the light emitted from it is more than single-line cut 9 lights and linear lights. The cut is 6. Consequently, this light has been used in a smaller amount.

It is worth mentioning that 9cm two-line linear lights are suitable for spaces with a height of more than 3 meters due to the large amount of light they emit, so glare to the human eye is not caused.

What is the time interval between the order of linear light and its production and installation?

One of the important points for designers, builders as well as architects, and decorators is the time interval between the order of the lamp and its installation, which may cause some concerns since many of the lights in the market are not domestically produced and therefore it is not possible to supply parts also it is a time-consuming process.

Meanwhile, Ecowat, as an important manufacturer of linear light engines with Zhaga standard, has eased the mind of our customers in terms of supplying linear light engines. All linear light devices, including light engine, body, and diffuser, are produced in the Ecowat factory, and as a result, the time interval between ordering a linear light and producing and supplying its parts is greatly reduced, and you can easily receive your orders as soon as possible. This issue will solve all concerns about the speed of production and customization of the lamp. For instance, the linear modules needed to illuminate 10 meters of linear lights are produced in less than 3 minutes, so your customized linear light can be made in a short time.

Price calculation and estimation of linear lights

Linear light is one of the most modern lights in the lighting market. It is for this reason that architects, designers, construction managers, employers, or purchasing and procurement managers may be very familiar with these lights and know the wide price difference of linear lights in the lighting market. Meanwhile, due to the nature of their design (Shape, length and etc) calculation of the price of linear lights has always been a challenge. In this article, we have analyzed how to calculate the price of a linear light, so that you can easily calculate the price of the linear lamp you want.

Factors affecting the price

- Installation Method

- Dimensions

- Linear light operation system

In general, the price of modular linear lights is higher than LED strings and non-modular linear lights. The reason for this is the longer lifespan of these lights and the reduction of maintenance costs in modular linear lights due to the ability to separate and replace each part individually.

Meanwhile, the modular linear light with modules and a constant current driver is more expensive than the ones with modules and a constant voltage driver. Because in the constant current linear light, there is no longer any electrical resistance on the light engine board, in addition to producing less heat, the light at the beginning and the end of the lamp is never different, but in the constant voltage linear lamp, there is much more energy loss. Also, it is possible that at high lengths of the light, the light will gradually drop in the path due to passing through many resistances.

Another difference in the performance of linear lights is related to the number of module lines and how they are placed. In some linear lights, to produce more light, two rows of chips and modules are used side by side and in parallel to radiate more light than usual. These two-line linear lights have a higher price compared to others, but they are very practical and cost-effective for providing the light of two linear lights in one light.

Which ones are the cheapest and the most expensive?

In general, it can be said that among linear LED lights, the cheapest ones are LED filaments or lights that work with the same performance system as LED filaments. The advantage of these lights is their low price, but with a mountain of problems including but not limited to bad quality and light loss, non-observance of the lighting principles in these lights by moving the thread, low light, short life span, and difficulty and high cost in repair.

The most expensive linear lights are modular linear lights with constant current, in which RGB technology and the Dali system are used for intelligent light control. In general, these linear lights, by working in smart systems, both double the beauty of the space and meet all the needs of a super professional. Overall, it can be said that constant current modular linear lights are the best linear lights in the market.

How to calculate the cost of your linear light?

Linear lamp manufacturers are divided into two categories. The first category does not have the ability to customize its linear lamp and they provide this lamp only in specific dimensions. Buying this model of linear lamp is similar to buying other lamps such as halogens and there is no need for any calculation.

The second group of manufacturers, which most architects and designers go to for lighting projects, produce linear lights in your custom dimensions. Usually, this group of linear light manufacturers price the lamp based on meter length. This means that the declared price is related to each meter of the light you want. In this case, it is enough for you to know the final price of your customized light by multiplying the unit price by the desired length to get the final price.

Does the customization of the linear lamp have an effect on its price?

Usually, linear light manufacturers such as Ecowat customize the linear light based on your needs without adding cost. For example, there is no difference between the price of 16 meters of square linear lights, 4 meters by 4 meters, or 16 meters of continuous linear lights. But some linear light suppliers may charge you an additional fee for custom-made light connections.

Tips that you should pay attention to when ordering:

1- CRI>90

One of the important points related to the quality of the light output of the lamp is the color rendering index or CRI. The color appearance index shows the degree of similarity that the color of the objects under the light of the lamp has, to their real color under the sunlight. Since linear lights are one of the most popular lights among architectural designers and activists, it is important that they can meet their expectations in every way, including the appearance of the color. Therefore, the best linear lights are the ones that have a color rendering higher than 90 or even 95 using quality chips.

2- Flicker-free

Another important factor in basic and modern lighting is flicker-free lights because flickers cause eye fatigue and headaches, and from this point of view, it is important that the people present in the space lit with linear lights do not feel tired or uncomfortable in any way. The old linear lights in the market are one of the flickering examples of these lights.

3- Uniformity of light along the optical line

One of the most important issues related to linear lights is the uniformity of the light along the optical line. The absence of dark and bright points or the uniformity of the light color is one of the most important points that add to its beauty and elegance in lighting with linear lamps. For this purpose, it is necessary for the light to be cut correctly at mint joints and angled places, and its SDCM index should be less than 3, so that no chip or module has a color or light difference from other parts of the lamp in terms of light color, even in a continuous line which might even be several hundred meters long.

Where to order linear lights?

LED linear lights are sold in different markets in different ways, either in person or offline, on various websites, you can see different types of linear lights with different uses and qualities.

You can contact us through the contact number +9821-58642 (Iran branch) or (Turkey branch) for any consultation and purchase of linear lamps. You can also text us on whatsapp messenger.